What are the basic characteristics of the thousand wheel ?

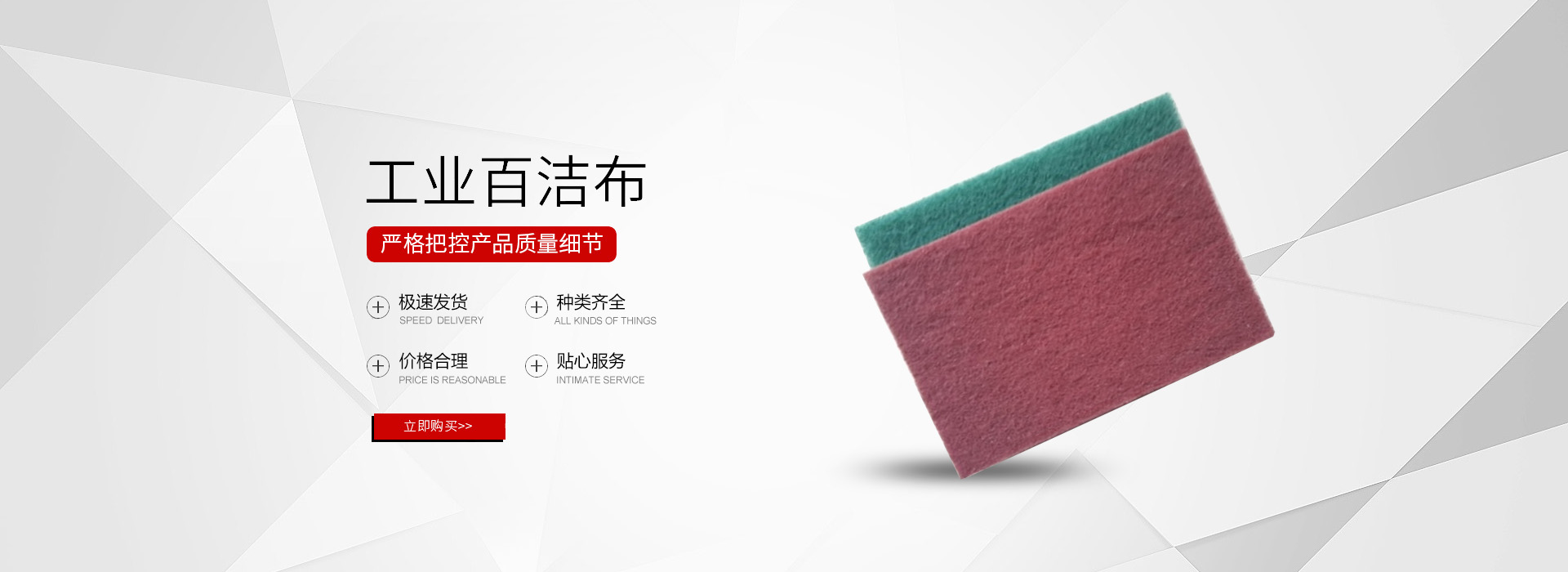

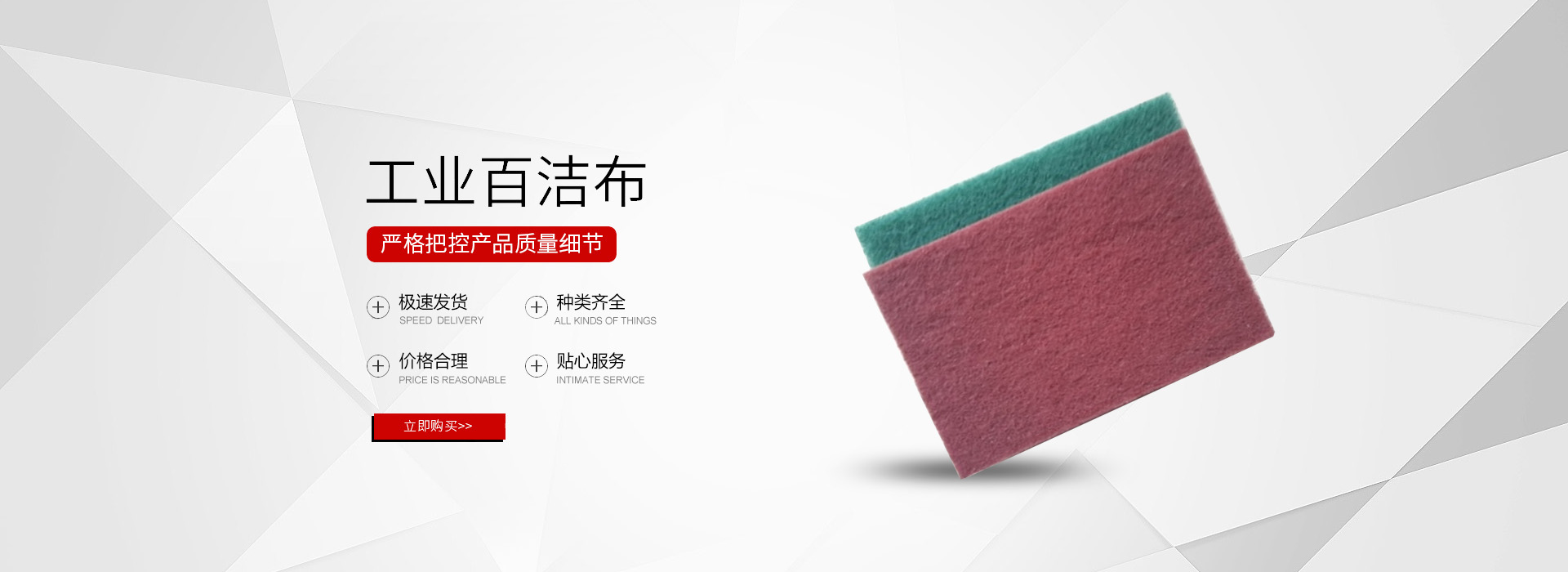

Chiba wheels are made of sand as raw material and are used for polishing both metal and non-metal surfaces. It has functions such as repairing welds, removing burrs, and removing rust from complex profiles. It has the advantages of simple assembly, low noise, smooth operation, and uniform surface treatment effect. Suitable for grinding and polishing in industries such as metallurgy, machinery, stainless steel, wood products, furniture, plastics, melamine, hardware, automotive, leather making, textile, etc. Chiba wheels have the following characteristics: 1. High balance and no strong vibration during rapid operation. 2. Moderately adjust the abrasive composition to make it sharp during grinding, with good penetration, and suitable for surface polishing. 3. Sandcloth blades have high strength, good flexibility, and are not easily broken. 4. The Chiba wheel adopts high-performance adhesive and bonding technology, and the overall durability of the Chiba wheel can withstand large impact forces. 5. A specialized resin sand cloth designed and manufactured based on the high hardness of the oxide layer on the outer surface of the heat pipe, used to make thousands of impellers, improving their usability by 20-30%. Chiba grinding wheel can be used for rust removal, paint removal, burr removal, and weld polishing on various surfaces of metal and non-metal materials such as shipbuilding, automotive, aviation, machinery, instruments, bridges, and construction industries, as well as furniture.

Chiba Wheel Product Features: This product has a hard working surface, sharp cutting, high processing efficiency, stable physical and chemical performance, high safety, and easy continuous operation. Compared to manual polishing, it saves time and is a high-quality Volkswagen polishing product for surface treatment.

- Previous:Already the first article

- Next:What are the basic characteristics of the thousand wheel

Chinese

Chinese English

English